Environmental Report

WE SET TARGETS AND IMPLEMENT ACTIVITIES BASED ON ENERGY SAVING, RECYCLING, AND RESOURCE SAVING, WHICH ARE KEY THEMES OF OUR ENVIRONMENTAL POLICY.

As for energy saving, both Nagaoka Factory and Mitsuke Factory are working to improve production efficiency as much as possible although energy usage in our production activities tends to increase year by year as we aim to produce high value-added products.

For recycling, we promote the reuse of product cases. We are conducting this activity by examining a method of approach considering efficiency and profitability in response to the changing circumstances.

For resource saving, we are developing and improving new resource-saving tools and long-life tools through the development of manufacturing equipment and will strive to supply products that are recognized by more customers.

Improvements

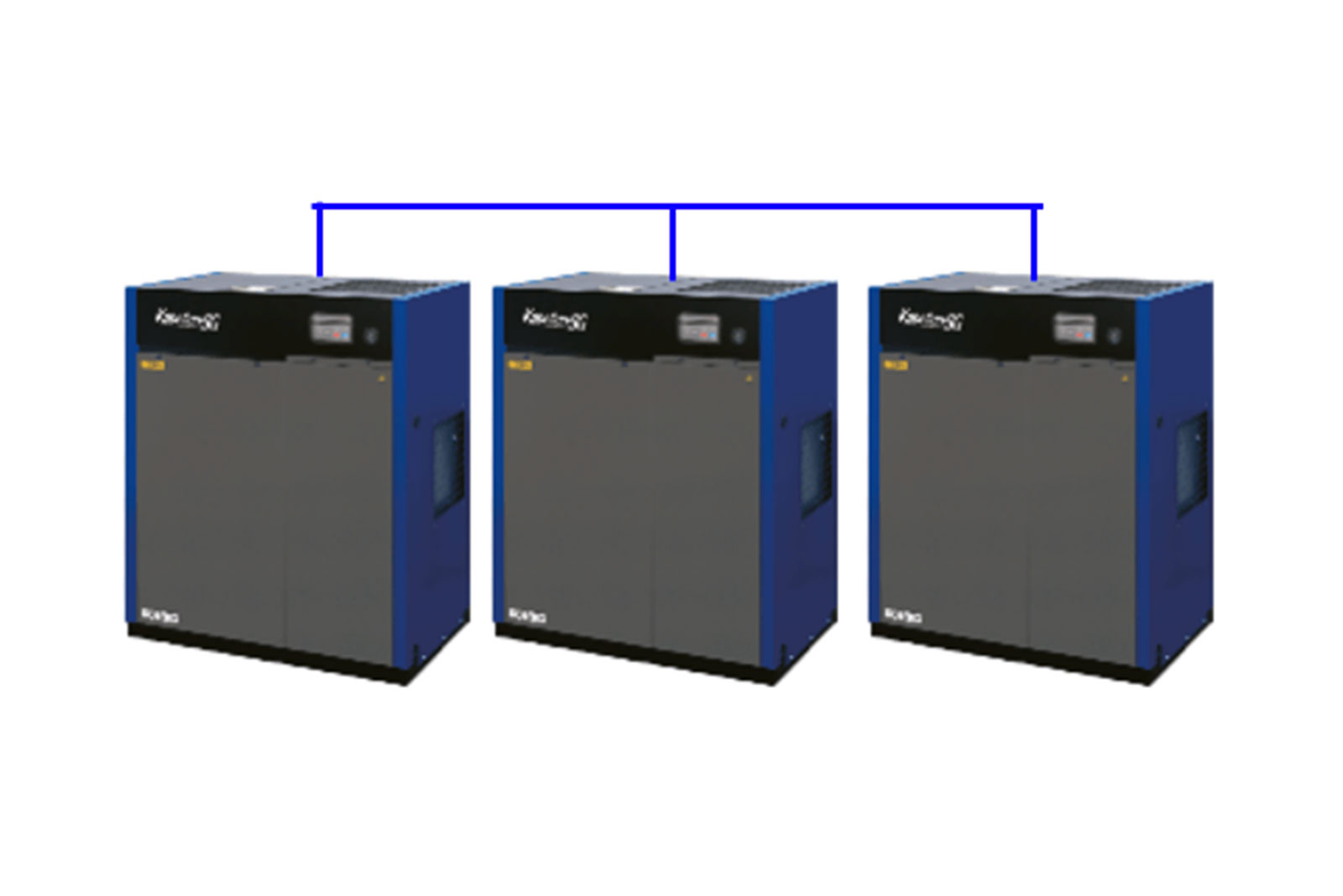

Mercury lamps changed to LED lighting and Compressors are controlled by communicating with each other.

Energy Saving

STRATEGIES OF ENERGY SAVING ACTIVITIES TO HELP REDUCING ENERGY CONSUMPTION IN OUR FACTORIES

In FY2020, Nagaoka and Mitsuke Factories conducted energy saving activities with a target of reducing energy consumption by 1% compared to FY2019.

As a result of such efforts, both factories achieved their targets; they reduced energy consumption by 3.28% and 2.06% respectively.

Since FY2014, we have been gradually introducing LED lighting systems into our factories.

In FY2020, all lights within Nagaoka Factory were replaced with LED lighting except for locations used for special applications. Mitsuke Factory is also planning to replace all lights by FY2022.

As a measure to reduce power consumed by pneumatic equipment, we have also introduced a mechanism to control the number of compressors used according to the usage of air.

Improving productivity is always a challenge for manufacturers and we are also focusing on the development of highly efficient equipment in our technical departments, leading to energy conservation.

We will continue to engage in efficient production activities from a broad perspective.

Recycling

WE COLLECT AND RECYCLE DRILL CASES.

Originally, it was a part of our in-house recycling operations. However, as its importance increased in our environmental activities year by year, it needed to be considered as a professional activity. For that reason, we have outsourced the drill case collection and recycling operations to a contractor since 2016.

We believe that the recycling leads to not only an effective use of resources, but also delivery of higher quality and lower price products more quickly to our customers. Considering as one of important operations, we will continue to promote recycling by setting targets.

Therefore, it would be highly appreciated if our customers and partners understand such efforts and cooperate in using the drill cases as cleanly as possible so that they can be reused over a longer life cycle.

Topics

When PCB drills are used, a part called “drill ring” is sometimes used with them. The used drill rings are provided to a welfare institution, where they are reborn as a beautiful ring art.

Green Procurement

IN ORDER TO PROVIDE CUSTOMERS WITH PRODUCTS THAT ARE FRIENDLY TO THE GLOBAL ENVIRONMENT WITH LESS ENVIRONMENTAL LOAD, WE MUST ACTIVELY USE ECO-FRIENDLY MATERIALS AND PARTS.

To ensure the reliability of our products, we not only comply with the RoHS Directive in Europe and other chemical substance-related regulations increasingly demanded throughout the world, but also follow our Green Procurement Guidelines when purchasing materials and parts.

Information on the hazardous substances in products is shared among our Engineering Department, Material Purchase Department, and the relevant suppliers, who all work together to investigate and clarify the content of environmentally hazardous substances contained in all materials, parts, and packaging materials, etc. used in the manufacture of our cutting tools and linear motion bearings.

We will continue to strive to minimize environmental burden throughout the product life cycle, ranging from material processing to product use and the end of life.

We will appreciate your kind understanding and cooperation in our green procurement activities.

Environmental Education

OUR ENVIRONMENTAL MANAGEMENT DEPARTMENT PROVIDES ONGOING ENVIRONMENTAL EDUCATION TO ALL EMPLOYEES WORKING IN OUR FACTORIES IN ORDER TO RAISE ENVIRONMENTAL AWARENESS AND PROVIDE THE RELEVANT KNOWLEDGE.

We employ four purpose-specific levels of education. The first level of education is our “new employee education” provided to new recruits upon employment, then followed by “general education” conducted on various themes every month to systematically raise the level of education of our employees.

The third level of education is “basic education”, which covers basic environmental issues and regulations related to business activities, after that followed by “specialized education” which covers more specialized environmental education.

To improve the quality of our education, participants undergoing “general education” are asked to complete a survey and the results are used as a reference for the selection of future themes and to improve the skill of our instructors.

These environmental education programs lead to the development of human resources who can maintain our corporate culture of “Love nature, Love people, and Love work”.

Collecting used postage stamps

REFORESTATION PROJECTS IN ASIA AND AFRICA

We collect used postage stamps and donate them to “The Defense of Green Earth Foundation (DGEF)“, who then sells these stamps in order to raise money to reforest areas in Asia and Africa.

Other than our employees, shareholders and customers that approve also support us in this activity.